3t Digital Store

Mechanical Joint Integrity

Couldn't load pickup availability

Buying for a business? Get in touch with sales@3t-transform.com

| CODE | T040 |

| DURATION | 120mins |

| LANGUAGE | English UK |

| EXPIRY | Never Expires |

Level:

Awareness

Target audience:

All relevant personnel.

Course Goal/Description:

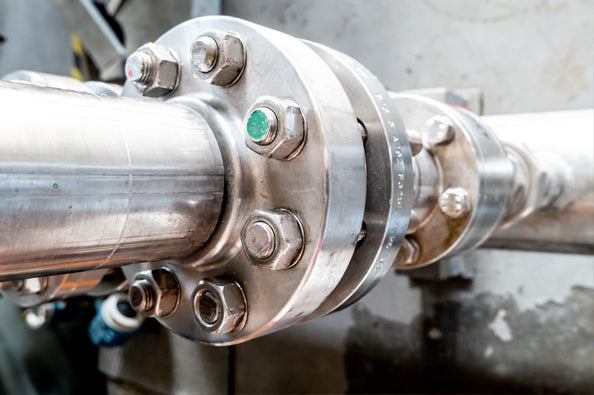

This course provides an overview of industry best practice in relation to mechanical joint integrity. It focuses on the individual components of bolted mechanical joints, the principles of joint assembly, hand and hydraulic torque bolted connections, and hydraulic tensioning of bolted connections.

Learning Objectives:

LO1 Explain the importance of mechanical joint integrity

LO2 Define what mechanical joint integrity is

LO3 Identify and describe the main components of a mechanical joint

LO4 Identify and describe the different types of flanges

LO5 List and describe types of gaskets and their use

LO6 Describe the role of bolts and nuts within a joint

LO7 Identify the principles of joint assembly

LO8 Explain importance of flange alignment and managing stress

LO9 Explain the purpose of tightening, and bolt load

LO10 Identify methods of tightening

LO11 Define what torque is and its use within a flanged joint

LO12 Describe how torque is calculated

LO13 Explain the role of friction when applying torque

LO14 Describe the role of lubrication

LO15 Identify the factors that affect torque tightening

LO16 Explain the use of bolt load calculations

LO17 Describe how bolts can be tightened by hand using torque wrenches

LO18 Describe the bolt sequencing requirements

LO19 Describe load loss and the role of auditing

LO20 Identify the types of bolt tightening failure

LO21 Describe hydraulic methods of tightening

LO22 Explain how a hydraulic bolt tensioner works

LO23 Describe why load loss happens and how to calculate load transfer factor

LO24 Describe break loose checks

LO25 Identify the methods of assuring bolt load

LO26 Identify the advantages of using hydraulic bolt tensioners

LO27 Describe what breakout torque is and how to dismantle bolted connections

Share